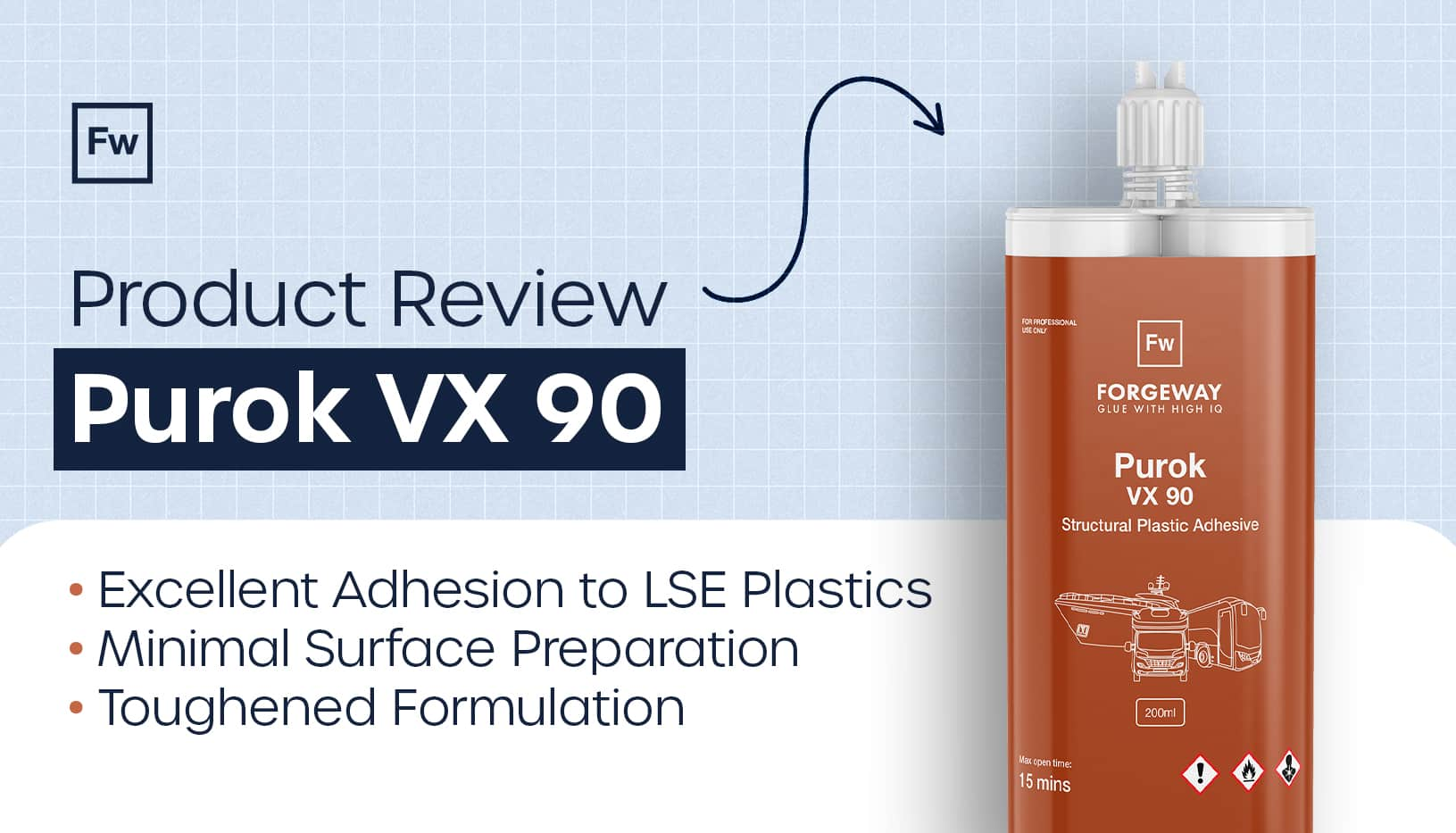

Purok VX90 product review; The ‘Primerless Polypropylene Adhesive’

You’ve heard about the ‘Primerless Polypropylene Adhesive’ (also known as Purok VX90), and now you want to know whether it is a good fit for you.

Here at Forgeway, we manufacture over 3000 tonnes of adhesive products every year. Purok VX90 is one of our newest developed products. It may be difficult for you to find the information needed.

We wrote this article to review the product and help you decide whether Purok VX90 is a good fit for you. We will discuss what the product is, where you can use it, and the benefits and drawbacks of using the ‘polypropylene bonder’.

By the end of the article, you will be able to decide whether Purok VX90 is a good fit for you. But if you’d prefer to watch our video review instead, you can watch it below.

Purok VX90 is a methyl methacrylate-based adhesive. We designed it specifically for use with low surface energy (LSE) plastics.

The strength will vary depending on the substrate(s) you are bonding. However, you can expect strengths of 14Mpa when bonding polypropylene.

Purok VX90 comes in a 1:1 two-component cartridge. You can get various cartridge sizes ranging from 50ml, 200ml, and 400ml.

It gels within five minutes and has a working time of 20 minutes. This means you have 20 minutes to put the substrates in place before it becomes unworkable.

It will achieve handling strength within 24 hours and full strength in less than 72 hours.

What applications can you use Purok VX90 for?

Purok VX90 is also known as the ‘polypropylene bonder’ for a reason. You can achieve very strong bonds when bonding polypropylene which is notoriously difficult to bond.

However, as we have mentioned already, we created this adhesive to bond low surface energy plastics, not just polypropylene. You can also achieve strong bonds with other LSE plastics such as HDPE (polyethylene), polystyrene, and PTFE (aka Teflon®).

But, you don’t need to worry about VX90 being specific to just LSE plastics. You can also use Purok VX90 to bond other plastics as well as most metals.

Whilst VX90 will provide a strong bond to most substrates, we would recommend you look at other structural adhesives if you are bonding metal or other, high surface energy plastics. This is because Purok VX90 is a specialist product for low surface energy plastics. The fact that it can bond to other materials ultimately means it is suitable for bonding low surface energy plastics to other substrates. You don’t need to bond LSE plastic to LSE plastic to get a strong bond with VX90.

A common example of this is in the commercial vehicle industry. Polypropylene composite panels are a popular choice for the side panels of commercial vehicles. So if you needed to bond a polypropylene composite panel to the metal frame of a vehicle, Purok VX90 will be the perfect adhesive.

Obviously, the main advantage of using Purok VX90 is its ability to bond to low surface energy plastics. That’s not all though, there are several other advantages of using Purok VX90. This section goes through them.

- It is very high strength. Purok VX90 achieves strengths of up to 14 MPa when bonding polypropylene. It also caused substrate failure with ABS (6 MPa), polyethylene (4 MPa), and polystyrene (2 MPa). See the lap shear strength chart below.

- You don’t need to prepare the surface. As with all methyl methacrylate adhesives, you won’t need to prepare the surface to achieve a strong bond. However, we still recommend you wipe the surface of any contaminants before applying the adhesive.

- The cure time is quick. We have already discussed that it doesn’t take long for VX90 to reach handling strength. But handling strength is subjective. Using polypropylene as an example, it takes 24 hours for the adhesive to reach a strength of 6 MPa. At this point, the adhesive would be strong enough for it to hold itself in place while the adhesive reaches full strength.

- There is no exothermic reaction during the cure. Most methyl methacrylates have a high exothermic reaction temperature as they cure. Purok VX90 does not have this exothermic reaction though. So you will not need to worry about this exotherm leaving ‘witnessing’ on the substrate.

What are the disadvantages of using Purok VX90?

Whilst there are many benefits of using Purok VX90, there are a few drawbacks too.

- It isn’t very flexible. Most methyl methacrylates typically won’t have much flexibility. Purok VX90 is much the same. However, this is only an issue if you are bonding very rigid surfaces like metal. Plastics’ ability to flex will mean any vibrations and impact will be shared and not put solely on the adhesive causing it to fail. When using VX90 to bond plastics (like it’s designed for), this lack of flexibility will not be a problem.

- Can present a health risk. If you don’t handle the adhesive correctly it can present a health risk. However, if you follow the instructions on the safety data sheet, you will not have any side effects. You should also be aware that all methyl methacrylate adhesives are flammable in a liquid state.

- Low heat resistance. This is once again a common problem with methyl methacrylate adhesives. At around 110℃, the solid-state adhesive will start to turn into a gel. This affects performance and strength. Whilst this heat resistance is greater than that of polypropylene, it is less than that of polyethylene and PTFE.

How do you know if Purok VX90 is a good fit for you?

It is very difficult to know whether Purok VX90 will be a good fit for you. We understand that.

Here at Forgeway, we help hundreds of automotive/transportation manufacturers and construction companies decide which adhesive is best for them.

If you aren’t bonding LSE plastics then Purok VX90 is not a good fit for you. Whilst the adhesive may still work, there are likely cheaper and better structural adhesives out there.

If you don’t mind preparing the surface before applying the adhesive and want a more flexible product that still bonds to LSE plastics, using a specialist surface activator with an MS polymer adhesive may be a better fit for you.

However, if your company is looking for an adhesive that will bond to low surface energy (LSE) plastics with no surface preparation required, Purok VX90 will be a good fit for you. Book a meeting with a consultant to see how you can get Purok VX90 to help you bond LSE plastics.

Still stuck on what is best for you? One of our team would be more than happy to help you decide whether Purok VX90 is a good fit for you.

Migelo turns technical jargon into clear, easy-to-read content. Forgeway’s mission is to address every question our customers and prospective clients have, even the ones they might hesitate to ask.